¿En qué se diferencian los filtros de agua industriales de los filtros de agua domésticos?

In modern society, water filters have become indispensable equipment in households and industries. Although their basic functions are similar to improve water quality and remove impurities from water, industrial water filters and household water filters are significantly different in design, function, performance and application range.

This article will delve into the differences between these two types of filters and analyze their applications and importance in their respective fields.

How do industrial water filters differ from household water filters?

Different design and structure:

1. Household water filter:

Home water filters are usually compact in design and suitable for home use. They mainly include the following types:

● Activated carbon filter: Mainly used to remove chlorine, odor and organic compounds from water.

● Reverse osmosis filter: removes dissolved solids and contaminants from water through a semipermeable membrane.

● Ultraviolet filter: Use ultraviolet rays to sterilize and remove microorganisms in the water.

Designed to ensure that family members have safe, clean water to drink, these filters are relatively simple to install and maintain, often fitting directly under the faucet or kitchen counter.

2. Industrial water filter:

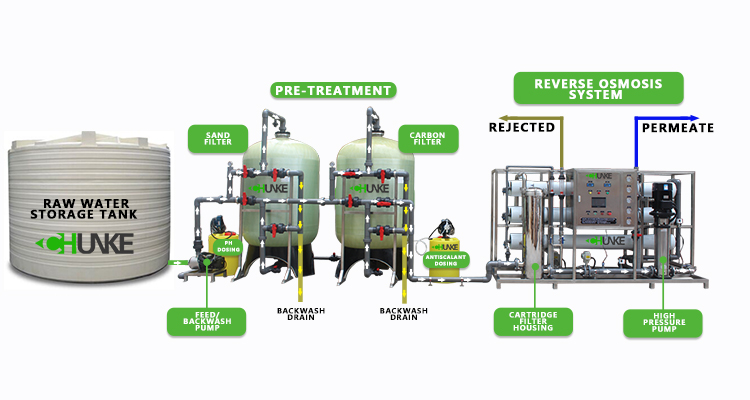

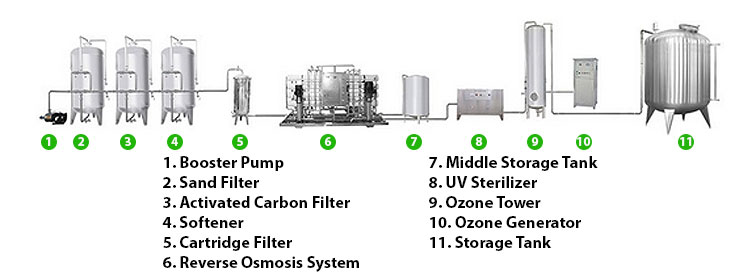

Industrial water filters are more complex and diverse, and their designs vary according to different industrial needs. Common industrial filter types include:

● Sand filters and multi-media filters: used to remove large particles and suspended solids.

● Microfiltration and ultrafiltration systems: used to remove tiny particles and bacteria.

● Reverse osmosis system: used for desalination and removal of dissolved solids.

● Ion exchanger: used to soften water and remove specific ions.

These filters are designed not only for filtration efficiency, but also for the ability to handle large volumes of water and durability to handle the harsh conditions found in industrial environments.

Function and performance are different:

1. Household water filter:

The main function of a household water filter is to provide high-quality drinking water, and its performance indicators are mainly focused on:

● Remove chlorine and odor: Improve the taste and smell of water.

● Remove harmful substances: such as lead, mercury, cyanide and other heavy metals.

● Sterilization: Remove bacteria and viruses from water through ultraviolet light or other means.

The performance of household filters is usually based on flow rate (such as how many liters of water are filtered per minute) and filtration accuracy (such as the pore size of the filter element) as the main indicators. In addition, the replacement cycle of the filter element and the convenience of operation are also important considerations.

2. Industrial water filter:

The functions of industrial water filters are more extensive and their performance requirements are also higher, mainly reflected in:

● High processing capacity: capable of processing large-scale water volumes to meet the needs of industrial production.

● High filtration precision: removes fine particles and dissolved matter to meet specific industrial standards.

● Durability and reliability: Able to operate stably for a long time under harsh conditions such as high pressure and high temperature.

● Multi-level filtration: A multi-level filtration system is usually used to ensure that water quality meets strict industrial standards.

For example, in the electronics manufacturing industry, water purity requirements are extremely high, and micron or even nanoscale particles may affect product quality; in the food processing industry, water safety and hygiene requirements are equally stringent.

Different application ranges:

1. Household water filter:

The application range of household water filters is mainly focused on household drinking water and domestic water, including:

● Kitchen water: filtered water for drinking and cooking.

● Bathroom water: Remove chlorine and hard water minerals from the water to improve the bathing experience.

● Whole-house water supply: Through the central water purification system, filtered water is provided throughout the house.

The purpose of using these filters is mainly to ensure the health and quality of life of family members and to prevent pollutants in tap water from affecting human health.

2. Industrial water filter:

Industrial water filters are used in various industrial fields, including but not limited to:

● Manufacturing industry: used for water quality treatment in cooling systems, process water and cleaning processes.

● Chemical industry: remove impurities in water to prevent adverse effects on the chemical process.

● Food and beverage industry: ensure the hygiene and safety of production water and prevent product contamination.

● Electric power industry: used for boiler feed water treatment to prevent boiler scaling and corrosion.

● Municipal water supply: Large-scale treatment and supply of drinking water to ensure water quality meets public health standards.

These fields have different water quality requirements, so the design and application of industrial water filters are more complex and diverse.

Maintenance is different from cost:

1. Household water filter:

Maintenance of household water filters is relatively simple and mainly includes:

● Regularly replace the filter element: Depending on the usage and filter element type, it is usually replaced every 3-6 months.

● Cleaning and Disinfection: Certain types of filters require regular cleaning and disinfection to prevent bacterial growth.

● Test water quality: Use simple water quality testing tools to ensure filtration effectiveness.

The cost of household filters is lower, mainly including the initial purchase cost and the cost of filter element replacement. For ordinary families, these costs are acceptable.

2. Industrial water filter:

The maintenance and operation of industrial water filters are more complex and expensive, mainly including:

● Professional maintenance personnel: Professional technicians are required for regular inspection, maintenance and troubleshooting.

● Equipment maintenance and replacement: Equipment such as filters, pumps and pipelines require regular maintenance and replacement to ensure long-term and stable operation of the system.

● Chemicals and consumables: Some filtration systems require the use of chemicals for cleaning and maintenance, which increases operating costs.

Due to the large-scale water volumes and high water quality requirements that industrial water filters treat, their initial investment and maintenance costs are significantly higher than that of household filters. However, for industrial production, good water quality is an important factor in ensuring product quality and production efficiency, so these investments are necessary and worthwhile.

Conclusion on Industrial Water Filters vs Household Water Filters

To sum up, there are significant differences between industrial water filters and household water filters in terms of design, function, performance, application range and maintenance costs. Household water filters mainly provide families with safe and clean drinking water, and are designed to be simple and easy to maintain; while industrial water filters need to deal with complex water quality problems and have higher processing capabilities and durability to meet the needs of various industries. production needs.

Understanding these differences can help users choose appropriate water filtration solutions in different scenarios to ensure safe and healthy water quality.

Comprender estas diferencias puede ayudar a los usuarios a elegir soluciones de filtración de agua adecuadas en diferentes escenarios para garantizar una calidad del agua segura y saludable.